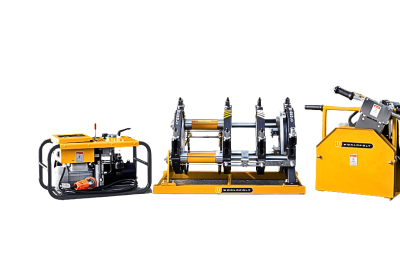

'European Style' Machines

- Designed and engineered in Australia, to reflect the true requirements of the market:

- Pipe OD is not within manufacturers tolerances, so the machine must re-round it for welding. Our main clamps are heavier because of that, and yes, that costs us.

- Electrical wiring is done according to the requirements of the IEC, which is not the case with low-cost copies. Good luck if somebody is electrocuted using one of those.

- Worldpoly hydraulics are sized according to real-life, not theory. Most clients weld 12 metre, not 6 metre lengths as is the case in Europe, and real-life contractors not in Europe have their own ways, so our hydraulics provide the power you need. And yes, you pay for that.

- Our ‘European Style’ and workshop machines are produced according to specific requirements. We’ve been doing that for 20 years and we’re pretty good at it, but we must continue because you won’t pay for us to make them in Australia. Facts are facts. That production centre manufactures exclusively for Worldpoly, is fully integrated with our Australian Design Centre, and produces the best butt welding equipment coming out of China. PolyForce machines are 100% Australian-made.

- ‘Fitness for Purpose’ is the Law in Australia, and all of our butt welding machines follow that basic requirement, no matter where we supply them. That’s a very old fashioned attitude, it’s what we are.

- Worldpolys history began with the production of poly pipe in 1959 and has been a part of its use in more that 100 countries, so please, ask any questions from the most basic to material analysis and testing. Wherever you're at in the use of HDPE pipe, we’re sure to have an opinion.

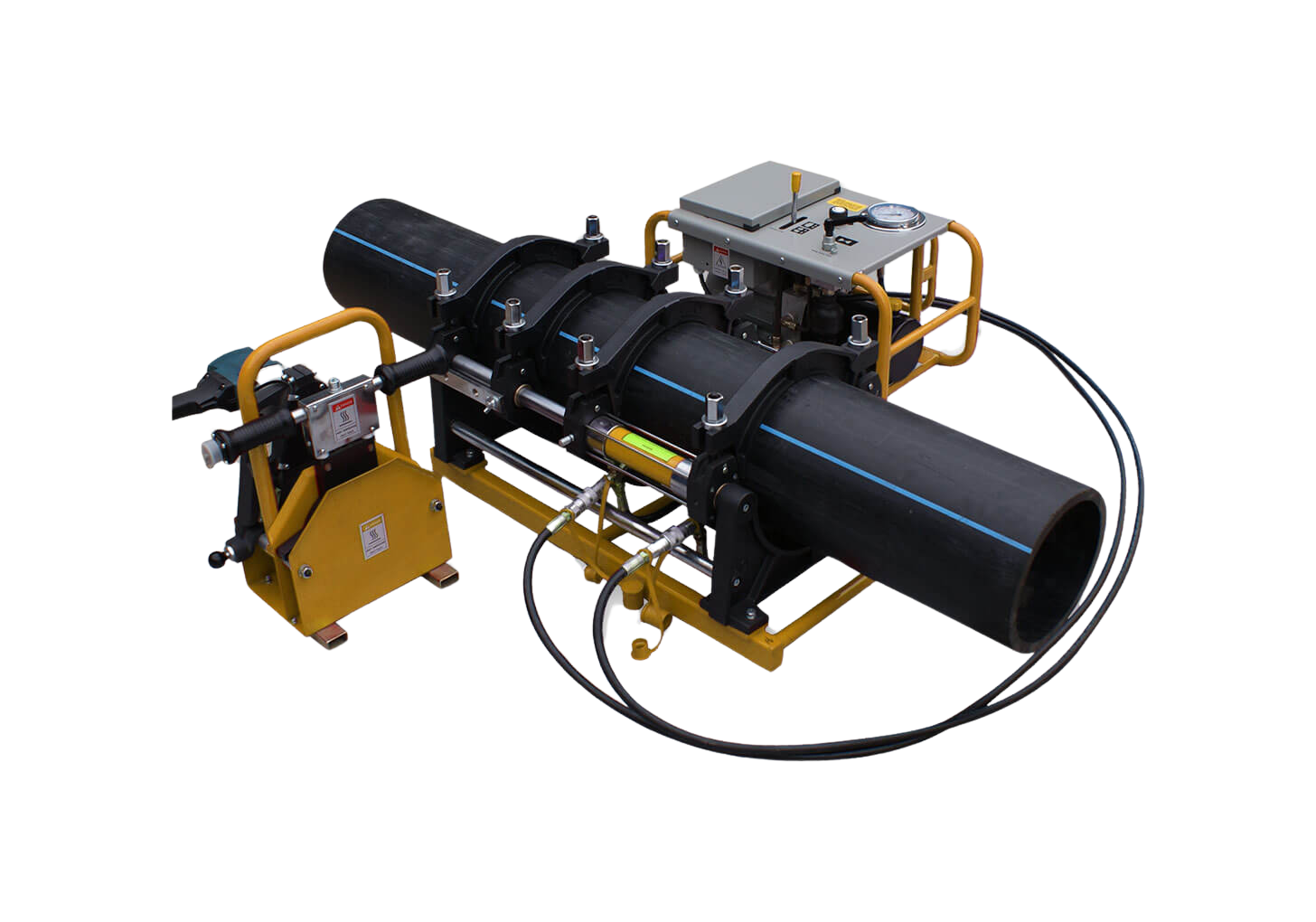

'North American' Style Machines

"North American" style machines have all of the components on-board, with the tracked versions carrying their own power supply.

"European style" machines are by far the most popular world-wide, due to their significantly lower price. On a Dollar for Dollar comparison it looks like a no-brainer, but site location, labour costs and availability, the requirement for speed and accuracy, local health and safety considerations remind me what I was told decades ago ‘the Dollar sign is the last elements of the value equation, otherwise Mercedes Benz wouldn’t exist’. You can buy a machine from us to weld 630mm/24” pipe for AUD 18,000 / USD 15,000 (Worldpoly630), or for AUD 400,000 / USD 300,000 you get a fully optioned PolyForce630i Tracked.

Worldpolys’ PolyForce tracked machines are completely designed, engineered and manufactured in Australia, according to the requirements of our particularly stringent health and safety requirements, difficult environment and climate, and the requirements of clients welding under difficult conditions.

The availability of parts has always been an issue for imported machines, which is why PolyForce uses only locally supplied components. Whatever you need we can take from either work-in-progress or our normal supplier, and have you working ASAP, so there’s no need to cannibalise a $400,000 to keep another one working. If you are in North America our suppliers Rexroth, Danfoss, Yanmar, MecAlte etc. have extensive cover over your way, so were more than happy to do any warranty work with them and your favourite hydraulics or electrical specialist.

Some specifics of our PolyForce Tracked machines are:

- All PolyForce machines are 100% Australian designed, engineered and manufactured, from more than 60 years of experience.

- PolyForce630i Tracked is supplied as a complete machine, no extras. All diameters of liners, data logging, trench kit, no surprises.

- Provides full PLC welding with automatic time, temperature and pressure, semi-automatic and manual welding.

- Easy, intuitive operation removes operator variables.

- Allows welding between clamps 2 & 3, and 3 & 4 for short fittings, fabrications etc.

- Automatic changeover following heating happens in 6 seconds, consistently reducing what is considered to be a significant cause of long-tern weld failure.

- All liner diameters are included with the original machine.

- Data logging to ASTM F3124-15 is included at no cost.

- Equipment for future remote connectivity has been included for a future software upgrade.

- PolyForce1000e provides welding to 1000mm / 36” DIPS, with a greater level of operator control.

- Track motors are ridiculously powerful.

- All diameters of pipe clamps, data logging and trench kit are included.

- Width is transport legal without removing the welding carriage, and it can be driven straight into a shipping container.

- Hands-free open/close/locking of main clamps.

- Uber-tough design and construction.

- More excellent customer service.